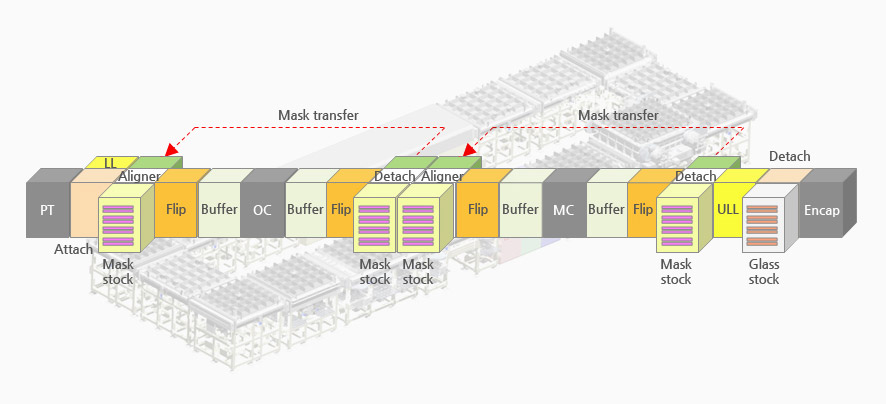

In-line system

Based on differentiated technology, CNI Technology had successfully led the project related to vacuum automation systems.

-

- Mask stocker

-

Mask stocker is a chamber that stores metal masks in

the 8th-generation OLED process.

It is configured with mask cassette, up/down module, and forward/backward roller module.

-

- Buffer chamber

-

Buffer chamber is a chamber that controls the gap between substrates

during the transfer of 8th-generation OLED substrates.

It increases the efficiency of using deposition materials

by reducing the gap between the substrates as much as possible and controlling it precisely.

-

- Load lock

-

The 8th-generation load lock is applied with fast pumping

and vent, low-particle generation technology.

As for driving rollers, the chamber volume has been reduced as much as possible

through the use of a ferro-seal direct connection type.

-

- Glass flipper

-

It is a chamber that reverses the glass to face up or down,

and it is possible to pre-heat or cool the glass at the same time.

-

- Carrier elevator

-

Carrier elevator is an equipment that interfaces with AGV/MGV and puts the carrier into a vacuum chamber.

It is configured with an up/down module and a sliding module.

-

- Liner Buffer

-

Linear buffer is an equipment developed to allow transfer

from a cluster tool to an in-line equipment.

It consists of a top linear stage, a bottom linear stage,

an up/down module, and an aligner.